Logitech tablet keyboard for android user manual. There are AAA batteries and Li-ion batteries embedded in the device that serves as a dual power supply. It sleeps after three minutes of inactivity and thus saves the battery consumption.The shape is upgraded and the design is ergonomic. It is best to use for any hand type. For a month of continuous use. The sleep mode is enabled in the keyboard.

ToolBarn.com is your source for pressure washers, pressure washer repair parts, and pressure washer accessories, we offer the largest selection from leading manufacturers including Karcher, Annovi Reverberi, Cat Pumps, General Pump, Comet Pump, Simpson and more. We stock products for all types of users, from residential use pressure washers and replacement parts to equipment used in industrial. We want you to be successful at what you do; to help you achieve this goal we provide the documents below. Hyundai accent 2007 user manual pdf. Here you can download advertisements, discontinued product information, brochures, end-user guides, material safety data sheets, parts lists, sell sheets, service manuals, warranty information,.

www Sony a300 battery charger.

Karcher Service Manual

.kaercher

.com/register-and-win

B 150 R

59662740 06/14

Lg tone active plus manual. Rechargeable.

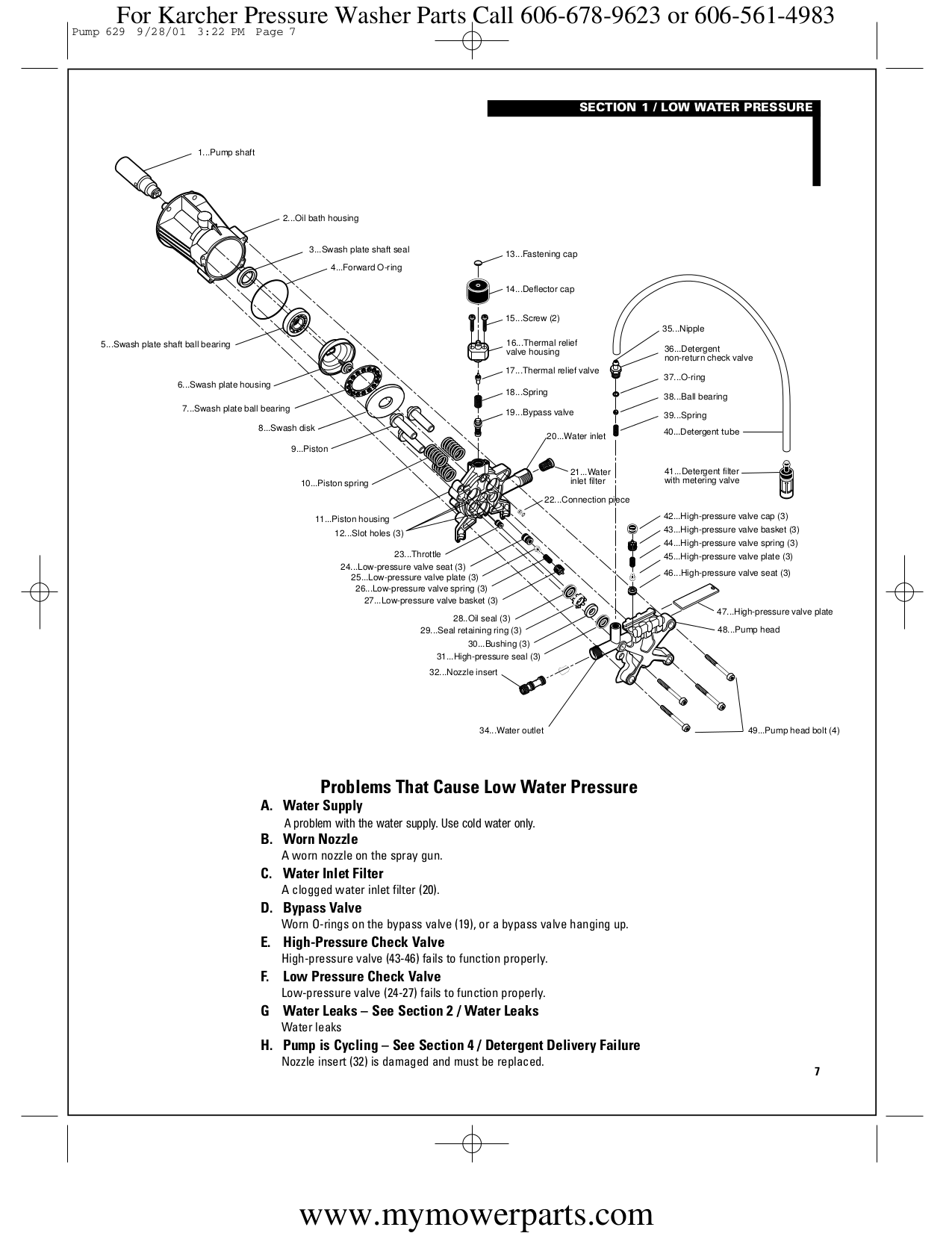

Karcher Pressure Washer Parts Manual

Autolaveuse B 150 R Advanced + R 75, Autolaveuse B 150 R + R 90, Autolaveuse B 150 R + D 75, Autolaveuse B 150 R Advanced + R 90, Autolaveuse B 150 R + D 90, Autolaveuse B 150 R Advanced + D 75, Autolaveuse B 150 R + R 75, Autolaveuse B 150 R Advanced + D 90, B 150 R Adv + D 75, B 150 R Adv + D 90, B 150 R Adv + R 90, B 150 R + D 90, B 150 R + R 90, B 150 R Adv + R 75, B 150 R + D 75, B 150 R + R 75

Karcher Repair Manual

Karcher 570

Karcher 570

Introduction

The success of our products is based on the ease and speed with which they are serviced. Proper and effective service is only possible given adequate, practical training and the provision of easily understandable service documentation. This handbook is designed to help you in your daily work, first as operating instructions and then as work of reference. It can also be used as a training manual. The information contained in this handbook has been revised up to the date publication, April 1990. It is not covered by our ammendment service. You will be regularly informed of modifications in our technical circulars. KARCHER CUSTOMER SERVICE TRAINING

All rights reserved The text and illustrations in this publication may not be reproduced in any form or be made available to third parties without the express permission of: ALFRED KARCHER GMBH & CO. Reinigungssysteme Postfach 160 D-7057 Winnenden

Contents

Karcher 570

Page 1 Page ................. 11 Schematic arrangement ............ 4 Functional faults 1. Relief valve does not lift 1. Operation with mains water supply 2. Detergent not drawn in 2. Operation with suction feed 3. Air drawn in with detergent 3. Operation with detergent 4. Water in detergent container 5. Injector defetive Operation with detergent 5

...........

1. High-pressure cleaning without detergent Internal water leakage 2. Low-pressure cleaning with detergent 1. Checking the suction valves 3. Detergent metering valve 2. Checking the pressure valves 4. Adjusting the doseage 3. Checking the relief valve 5. Switching over the 2-way nozzle

.............13

Function of the relief valve .......... 7

Visible water leackage ............. 15

1 Function with hand-gun valve open 2. Function with hand-gun valve closed 3. Pressure and flow regulation

1. Pressure and flow control 2. Leakage between cylinder head and

housing 3. Replacing the LP seal

.............8 1

Basic cleaner settings

I Oil Leakage ......................17

1. Checking the pump delivery 2. Checking the relief-valve opening

1. Oil drain plug leaking 2. Piston and housing oil seals leaking

pressure 3. checking the detergent feed 4. Checking the detergent flow

Rapid trouble-shooting Cleaner does not run

Pump defects ....................19

............10

.............

10

1. Piston jammed 2. Motor fan defective

Special tools ............:.........20

1. Motor does not run

2. Circuit breaker trips 3. Cleaner switches off after a short time

Cleaner does not come up to pressure .................... 10 1 . Water volume inadequate Water inlet filter blocked Pump not bleed of air Pump sucks in air Bore of HP nozzle worn too large

2. 3. 4. 5.

Technical data

...................21

Circuit diagrams..................22 1 . Power supply connection 2. Electrical circuit diagram

Technical modifications

...........23

Kiircher 570

Schematic arranaement

Detergent suction hose

Water supply connection

Non return valve

---------Water container Pressure and flow control valve

P

Hi h pressure hose

2-way nozzle C

1. Operation with mains water feed

The water from the main connection flows through the non-return valve to the pump and, when the motor is switched on, the pump delivers water under high pressure through the high pressure hose and hand gun to the 2-way nozzle. 2. Operation with suction feed

When the motor is switched on, the pump draws water from the water tank or container, through the foot strainer and delivers it at high pressure through the high-pressure hose and hand gun to the 2-way nozzle.

3. Operation with detergent When the2-way nozzle isswitchedtofan jet, detergent is drawn by the injector through the detergent suction hose and is mixed with the water delivered by the pump. On the Karcher 570 cleaner, the amount of detergent fed can be adjusted by means of a metering valve.

Operation with detergent

Injector connection

1. High-pressure cleaning without

detergent The water is pumped through the injector to the 2-way nozzle. The pressure at which the water leaves the nozzle depends on the size of nozzle bore, the larger the bore, the lower the jet pressure and vice-versa.

Karcher 570

Detergent suction hose

2. Low-pressure cleaning with detergent With the 2-way nozzle switchedto low-pressure (large nozzle bore), the water passes at high speed through the injector and this results in a reduction in pressure (vacuum) at the injectorconnection. Such avacuum is only generated if the bore of the nozzle is larger than the bore of the injector. The vacuum thus generated causes detergent to be drawn through the detergent non return valve and detergent metering valve, to be mixed with the water delivered by the Pump.

Kijrcher 570

Oneration with deteraent

Detergent metering valve

3. Detergent metering valve

4. Nozzle setting

Position closed The knob, which is pressed over the metering valve is turned counter-clockwise to screw the tapered end of the metering spindle out of the metering bore.

At normal working pressure (with the 2-way nozzle set to full jet 25'), there is no detergent feed. Detergent is only drawn into the water flow when working at low pressure, using the fan-jet nozzle (with the nozzle turned to 'CHEM').

If the metering spindle is turned counterclockwise as far as it will go, then a large quantity of detergent will be drawn into the water flow . If the spindle is turned clockwise as far as it will go, the valve will be completely closed and there will be no flow of detergent.

5. Switching the 2-way nozzle On Karcher570cleaners,the guard overthe 2-way nozzle is turned to low-pressure fanjet (CHEM).

Function of the relief valve

KBrcher 570

1. Function with hand gun open

At standard working pressure with the pressure and flow control valve turned to full water flow the relief valve is closed and the full pump delivery passes to the hand gun. 2. Function with hand gun closed

When the trigger of the hand gun is released, the pressure in the chamber below the relief valve piston increases and water passing through the bore developing a similar pressure in the chamber above the piston. Since the piston has a largerarea at the top than at the bottom (where its diameter is the same as that of the s~indle), ,. it follows that the applied the top of the piston (~ressure x area = force), is areater than the ' ibrce applied to the bottom and thus the force tending to press the piston and the spindle downwards is greaterthan the force (spring pressure) pressing it upwards. This causes the piston to open the valve spindle to allow water to flow between it and

thevalve seat, backtothesuction side of the pump. The gap between the valve spindle and the valve seat is such as to cause a circulation pressure of 10 bar to be applied to the greater effevtive piston area and thus to hold the valveopen against the spring pressure. When the trigger of the hand gun is pressed again, the pressure in the chamber above the piston falls completely away and the spring closes the overflow valve. The pump then builds up the standard working pressure once again.

3. pressure and flow control valve By turningthe knobonthe pressureand flow control valve, it is possible to partly open the relief valve so that some of the water delivered by the pump is caused to flow back to its suction side, thus reducing the pressure and flow of water delivered to the hand gun.

Karcher 570

Basic cleaner settings 1. Checking the pump delivery

Fit the HP outlet with the shutoff valve (special too1)connectthe HP hose (without hand gun and spray lance), start the cleaner. Close the shutoff valve as far as necessary to bring the cleaner up to working pressure (see Technical Data) and rneasure the quantity of water delivered into a suitable container in litres, or gallones per minute. If the quantity of water delivered is too low, this indicates leakage within the Pump. 2. Checking the pressure at which the relief vaGe opens

Fit the shutoff valve(special tool) to the HP outlet and start the cleaner. Slowly close the shutoff valve and note when the needle of the pressure gauge indicates that the relief valve has switched to circulation (approx. 10 bar). The switchover must take place on reaching a pressure of approx. 120 bar. ADJUSTMENT IS NOT POSSIBLE,THE PRESSURE DEPENDS ON THE DESIGN

Basic cleaner settings

Karcher 570

3. Checking the detergent feed

Start the cleaner and switch over to 'operation with detergent' by turning the 2-way nozzle to 'CHEM. With the meteling valve set to position '0, no detergent should be drawn into the cleaner. If detergent is drawn in, then the knob must be pulled off the metering spindle.

The spindle should the be turned hand tight to close the valve completely and then the knob should be pressed back on (the stop limiting the rotation of the knob is at the top on the cylinder head). 4. Checking the detergent flow

The maximum detergent flow is checked by turningthe knobto the maximumsetting and by then measuring the quantity of detergent drawn from arneasurement glass in a given time.

Detergent suction hose Hose nippel

Detergent metering spindle

Karcher 570

Rapid trouble shooting

Cleaner does not run

Cleaner does not come up to pressure

1. Motor does not run

1. Inadequate water supbly

Check main fuse or circuit breaker (10-16 Amp delayed action).

Checkwatersupply hose (not less than 112' i.d.). A supply of at least 600 litres of water per hour must be available.

Check the voltage at the power socket and compare it with voltage on the nameplate.

Ease the filter out with a screwdriver, clean it and press it back in by hand.

Check the switch on the cleaner. Check the motor capacitor

2. Water inlet filter i s blocked

/'

2. Circuit breaker trips or fuse blows

3. Pump not vented of air

Check main fuse or circuit breaker (10-16 Amp delayed action).

Switch off thecleanerand keep the triggerof the hand gun pulled until a steady flow of water emerges. Then switch the cleaner on again.

Extension cable has too small a conductor cross-section (see Operating Instructions).

4. Pump is sucking air

Extension cable not unwound from drum.

3. Cleaner switches off after running for a short time Check current consumption. Extension cable has too small a conductor cross-section (see Operating Instructions).

Turn off the water-supply valve and check the hose connection. If you are drawing water by suction from a tank, checkthatthesuction head isnot more than 0.5 metres (20). If necessary, fill the suction hose with water. 5. HP nozzle worn (bore too large)

Replace the HP nozzle and check the pressure. If the pressure is still too low, the fault is in the HP pump (measure pump delivery).

Function fault

Karcher 570

Special screw plug

Functional faults 1. Relief valve does not switch to

circulation Fault Relief valve does not close O-ring set defective Remove the housing cover Unscrew the special screw plug. Using an 8mm socketdriver, pressdownthe piston and by turning the piston, unscrew it from the valve spindle. Pull out the piston with some suitable pliers. Remove the O-ring set complete and replace it with a new set, using the special tool after applying silicon grease. Insert the piston in the zylinder head, screw it to the spindle. Use loctite (No. 6.869-002) to secure it. Screw in the special screw plug complete and tighten it with-a torque of 30 Nm. 2. No detergent i s drawn in

Detergent non return valve and O-ring sticking together. Pull the suction hose from the hose nipple. Unscrew the hose nipple using a 19 mm oDen ended wrench. ~ a u i i o n The : check ball could fall out. Remove the spring, ball and O-ring and clean them. Replace the O-ring (without grease), ball and spring. Note: The smaller end of the spring has to face towards the ball.

Karcher 570

Function faults 3. Air is drawn in when working with detergent

The detergent hose is not secured firmly.

/

Detergent suction hose

Hose nipple

Pull the hose off the nipple, cut off the end and press the hose back on. Leakage around the detergent metering spindle. Pull off the knob. Screw out the spindle.

Refit the spindle and knob.

Detergent metering spindle

4. Water in the detergent container

Detergent non return valve defective or incorrectly fitted. Pull off the suction hose. Unscrew the hose nipple. Remove and clean the spring, ball and O-ring in the hose nipple. Replace any parts as necessary. Insert the spring, ball and O-ring in the hose nipple (without grease). ,$

5. Injector defective

Screw out the injector with the aid of a suitable screwdriver. Replace the O-rings or, if necessary, replace the injector and O-rings.

Internal leakage

Karcher 570 Measuring the pumpdelivery indicates a loss of some water. Possible cause: The suction valve, delivery valve or relief valve defective. 1. Checking the suction valve

Remove the housing cover. Pull out the valve seat using special tool. Check and, if necessary, replace the valve seat and O-ring. Remove the valve plate and spring.

Torx screw

Checkthesealing surfacesof thevalveseat andvalveplate fordirt orgrooveand replace if necessary.

If necessary, replace the O-ring seal of the housing cover. Tighten the TOMscrews with a torque of 13 Nm.

2. Checking the pressure valves

Pressure valve

Unscrew the valve screw. Remove the pressure valve completely with the special tool. Check the sealing surface of the valve and replace if necessary. Pressthevalveintothecylinder head, screw in the valve screw and tighten with atorque of 30 Nm.

Wrcher 570

Internal water leakage 3. Checking the relief valve

Unscrew the special screw plug. Using an 8mm socket driver, press the piston downwards and unscrew it from the valve spindle. Piston Pulloutthe pistonwithpliersand removethe spring. Using the special tool, screw out the valve seat. Remove the valve seat and valve spindle from the cylinder head. Spring O-ring

Check the valve seat and valve spindle for damage or wear and replace if necessary.

Valve seat

If necessary, replace the valve-seat O-ring.

Valve spindle

Insert the valve seat andvalve spindle in the cylinder head and screw in firmly with special tool.

II

Insert the spring and piston and screw the piston on tightly. Secure the piston with loctite (No. 6.869002). Screw in the special screw plug and tighten with a torque of 30 Nm.

Visible water leakaae

Kiircher 570 1. Pressure and Flow Control

When there is leakage between the control spindle and the screw plug, then it is necessary to replace the special screw plug complete. Before screwing in the special screw plug, fit it with a new O-ring. Screw the special screw plug back into the cylinder head and tighten with a torque of 30 Nm.

Plastic washer HPSealrig

I

2. Leakage between the cylinder head and housing.

A leakage of one drop per minute is acceptable.

t-

Piston -

--

Housing Leakage bore

Visible water leakage

Ka'eher570

Plastic washer

Unscrew the cylinder head screws. Remove the cylinder head.

yher

I

Pull out the HP seal ring by hand or, if this is difficult, use a puller.

3. Leakage at the low-pressure seal

Pass a screwdriver through the leakage groove and carefully lever out the aluminium washer. Caution: Take care not to damage the piston. Replace plastic washer. Note: The crowned side of the plastic washer faces towards the cylinder head.

Grease a new HP seal ring with silicon grease and fit it using the special tool. Be sure to fit it correctly with the lips facing the cylinder head. Reinstall cylinder head and tighten the screws with a torque'of 15 Nm.

Oil leakage

Karcher 570 1. Oil drain plug leaking

Lay the cleaner on its side and unscrew the oil drain plug. Top off with correct oil. 6.288-050 SAE 15W40

Seal ring

Replace the seal ring and screw in the oil drain plug.

Oil drain plug'

2. Piston seals and housing seal leaking

Remove the cylinder head. Drain the oil and replace the drain plug seal ring. Screw assembly screws (extralong screws) into the housing. Unscrew the housing fastening screws. Caution: Loosen the assembly screws evenly as you draw ofl the housing.

Remove the housing together with the pistons.

Oil leakage

Mrcher 570

Pass a screwdriver through the leakage grooves and lever out the oil seal rings.

Caution: Take care not to damage the sealing surfaces in the guide.

Remove the O-ring. Clean the housing.

/O-ring

Note: The new oil seal rings should be soaked in water for some time before they are fitted. Without applying any grease, fit the oil seal rings in the housing using the special tool. Coat the O-ring with silicon grease and place it in the groove of the housing. Insert the pistons and springs in the housing. Pull the housing evenly into place by means of the assembly screws. Fill with app. 0.2 1 SAE 15W40 1 (6.288-050). Refit oil drain plug.

oil seal ring

Karcher 570

PumD defects Pump runs very noisily

1. Piston jammed, swash plate worn

Remove the cylinder head. Use the assembly screws to pull off the housing. Check the pistons for wear and, if necessary, replace the pistons and springs. Carefully lever out the oil seal rings with a screwdriver. Fit new oil seal rings without applying grease or oil. Checktheswash plate forwear and replace if worn. The motor is generally replaced complete with the swash plate. The swash plate can only be removed by pressing the motor shaft out of it in the direction of the motor cooling fan with a hand-lever press.

2. Motor fan defective

Pull ofl the motor cooling fan using the special tool. Press a new fan onto the motor shaft. Fit the fan cowling.

Wrcher 570

Special tools Part No.

1

Page

Shutoff valve

2.901 -030

8

O-ring insertion mandrel for relief valve piston

5.901 -104

11

O-ring insertion mandrel for detergent metering spindle

5.901-102

12

Valve pliers

4.901-062

13

Valveseat removal tool

4.901-054

14

Mounting mandrel for HP and oil seal rings.

2.901 -031

16

Puller for motor cooling

6.81 6-069

19

Technical datas

Karcher 570

I(

Cleaner type Part No. for cleaner Circuit diagram Part No.

Karcher 570 1.721-120

I1

From Serial No. 426281 1.721-120

0.087-354

0.087-354

Voltage

Volt

220

220

Type of current

PhlHz

1I50

1150

Full-load power consumption

Amp.

9,5

9,5

HP nozzle Working pressure - full load*)

bar

Working pressure - part load

bar

Circulation pressure

bar

Relief valve opening pressure

bar

Flow volume - full load

I/h

Flow volume - part load

I/h

-

-

Detergent flow - rnax.

-

I/min

*) on the cleaner's pressure gauge.

Karcher 570

Electrical connection 1. Electrical connection

L1

N

PE

The electrical voltage is connected from L1 to the motor M I by way of the motor switch S1. The phase L1 is fed by way of the thermal overloadtrip L1 to the main auxiliary winding Z1 of the motor. The capacitor is connected between the main and auxiliary windings C1. A lead from the main winding of the motor leads back to the neutral terminal N.

2. Circuit diagram Legend S1 Motor switch F1 Thermo contact M1 Motor Z1 Auxiliary winding C1 Capacitor

Technical modifications

Karcher 570

Modification as of April 1989

Old

New

Cylinder head

5.550-116

Delivery valve

Cylinder head

5.550-144

Delivery Valve 5.332-1 16 5.584-056 5.583-088

Spring Valve Pin Valve screw

Working pressure

Valve complete O-ring Valve screw

4.580-180 6.362-480 5.583-1 08

Working pressure

Cleaner's pressure guage

80 bar

Cleaner's pressure guage

90 bar

Calibrated pressure guage

68-78 bar

Calibrated pressure guage

80-88 bar

Spray nozzle 050

6.41 5-480

Spray nozzle 045

6.41 5-461

Spray lance

4.760-177

Spray lance

4.760-166

Connected load

1.85 kW

Connected load

2.00 kW

Modification kit: For cleaners with serial No. up to 423 780, there is a modification kit available to change over to the latest version. Modifikation kit No. 2.882-293 Modifikation as of December 1989

New

Old

The individual parts for the pressure and flow control spindle are still available.

The pressure and flow control adjustment can only be ordered complete with this part Nr. 4.401-054

Alfred Karcher Ges.m.b.H. Obachgasse 26 A-1220 Wien 22

Tel.: (02 22) 25 15 45 Fax: (02 22) 25154530

Karcher (Pty.) Ltd. 21158 Browns Road Noble Park 3174 Melbourne. Victoria

Tel.: Fax:

(03) 7 95 44 22 (03) 7 01 00 01

Karcher N. V. lndustrieweg 18 8-2320 Hooastraten

Tel.: Fax:

(03) 3 14 33 61 (03) 3 14 64 43

Karcher lndustria e Comercio Ltda. Estr. Mun. Campinas Paulinia, 2000 Betel 13082 Campinas - SP

Tel.: (01 92) 39 15 15 Fax: (01 92) 39 21 10

Karcher Cleaning Systems Inc. 1770 Alstep Drive Mississauga. Ontario L5S 1W1

Tel.: (4 16) 6 72 82 33 Fax: (416) 6 72 31 55

Karcher Vaporapid AG Industriestr. 16 CH-8108 Dallikon

Tel.: Fax:

Stammhaus: Alfred Karcher GmbH & Co. Alfred-Karcher-Str. 28-40 Postfach 160 D-7057 Winnenden

Tel.: (0 71 95) 14-0 Tx.: 07-24432 Fax:(O71 95) 1422 12

Karcher S.A. Tel.: Z.A. des Petits Carreaux Far. . 5, avenue des Coquelicots F-94865 Bonneuil s. MarneiCEDEX

(1) 43 99 67 70 (1 73 > , 43 39 48 ~~~

~

Karcher (U.K.) Ltd. Karcher House Beaumont Road Banbury Oxon, OX 16 7TB

Tel.: (0295) 26 75 11 Fax: (02 95) 26 64 36

Karcher S.p.A Via Eivezia 4 1-21050 Cantello (VA)

Tel.: (03 32) 41 74 00 +41 7419 Fax: (03 32) 41 83 50

Karcher Cleaning Systems Co., Ltd. Tel.: (03) 32 35-83 31 9-21, Shin Ogawa-cho Fax: (03) 32 35-83 07 Shinjuku-ku, Tokyo 162

Karcher AJS PO. Box 7 Veitvet N-0518 Oslo 5

Tel.: Fax:

Karcher B.V. Hermelijnweg 20 NL-4877 AE Etten-Leur

Tel.:

(0 16 08) '87400 Fax: (0 16 08) 1 43 48

Karcher AB Box 24 S-42502 Hisings-Karra

Tel.: Fax:

(0 31) 57 03 80 (0 31) 57 51 49

Karcher Oy Yrittajantie 17 SF-01800 Klaukkala

Tel.: Fax:

(90) 8 79 91 77 (90) 8 79 42 03

(02) 25 34 80 (02) . . 25 95 48

(01) 8 46 67 11 (01) 8 46 67 12

@ Karcher N S Hestehaven 21 DK-5260 Odense S

Tel.: Fax:

(65) 91 67 67 (65) 91 11 04

Karcher S.A. Pol. Industrial Font del Radium Calle Doctor Trueta 6-7 E-08400 Granollers (Barcelona)

Tel.: Fax:

(93) 8 46 44 47 (93) 8 46 55 05

Alfred Karcher Inc. Browertown Road and Andrews Drive P. 0. Box 778 West Paterson, N.J. 07424

@D

Karcher (Pty.) Ltd. P. 0 . Box 2417 Kempton Park 1620

Tel.: (2 01) 8 90 04 44 Fax: (2 01) 8 90 05 34

Tel.: (0 11) 9 76 31 00 Fax: (0 11) 9 76 22 44